Category

API 7K Drilling Pump Ceramic Liner Abrasion Alumina Ceramic Grinding Cylinder Mud Pump Spare Parts Liner

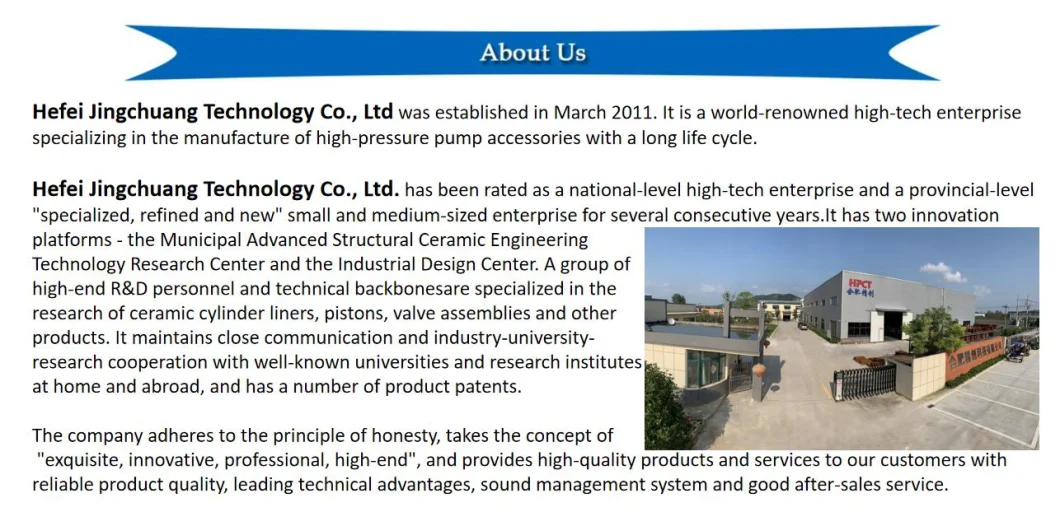

Our cylinder liner is composed of a pressure-bearing metal shell (45 # steel) and a high wear-resistant ceramic lining (

Basic Info

| Model NO. | All |

| Cetification | API |

| Application | Oil Drilling Rig Mud Pump |

| Outer Sleeve | Forged Steel 45# |

| Inner Sleeve | Ceramic |

| Hardness(Hra) | 180 |

| Model | F Series |

| Customization | Available |

| Transport Package | Wooden Box and Sea Shipment |

| Specification | 60 to 300mm |

| Trademark | customized |

| Origin | Hefei, China |

| HS Code | 84139000 |

| Production Capacity | 1000 Sets /Per Month |

Product Description

Our cylinder liner is composed of a pressure-bearing metal shell (45 # steel) and a high wear-resistant ceramic lining (zirconia). After precision machining and assembly, it has excellent overall mechanical properties, good corrosion resistance, high temperature resistance and high pressure resistance, which lasts longer than bi-metal liners, over 4000 hours, as well as has a lower overall cost.We could offer all the parts for the following mud pump model, or manufacturing as your drawing:

Bmoco | F500 | F800/1000 | F1300/1600 | F1600HL | F2200HL |

Lanshi | P2200 | 3NB-1600C | |||

Honghua | 3NB1600HL | ||||

NATIONAL | 8P80 | 9P100 | 10P130 | 12P-160 | 14P-220 |

RUSSIA | UNB 600 | UNBT 650 | NBT 600 | 8T-650 | UNBT 950\UNBT 1180 |

OILWELL | A-650-PT | A-850-PT | A1100PT | A1400PT | A1700PT |

WIRTH | TPK-1000 | TPK-1300 | TPK1600 | TPK2000 | TPK2200 |

List of Physical Characteristic Parameters of Ceramic Cylinder Sleeves

| Materialitem | Aluminum oxide | ZTA | Zirconia |

| Volume density(g/cm3) | 3.9 | 4.17 | 6.0 |

| Vickers hardness(GPa) | 13 | 12 | 11 |

| Bending strength(MPa) | 350 | 480 | 800 |

| Fracture tenacity(MPa.m1/2) | 4 | 5 | 9 |

| Young's modulus(GPa) | 370 | 330 | 200 |

| Abrasion resistance(min/cm3) | 15 | 35 | 40 |

| Linear expansion coefficient(40-800ºC)(×10-6/ºC) | 8.0 | 8.8 | 11.0 |

| Roughness(Ra)(μm) | 0.3 | 0.2 | 0.1 |

| Acid resistant(95%sulfuric acid,95ºC)(WT Loss,mg/cm2.d) | 0.25 | 0.2 | 0.04 |

| Alkali resistance(30%caustic sodium,80ºC)(WT Loss,mg/cm2.d) | 0.05 | 0.06 | 0.08 |

1.How can I get samples?

We can provide some free samples (total value under 15 US dollars) if you have a DHL, TNT, UPS or FedEXaccount or other courier freight collectable account and agree to pay the courier freight.

If the total value of samples is more than 15 US dollars, we'd like to ask you to pay for the samples and courier freight. We will send the samples to you after receipt of your payment.

If you don't have courier account, you can send your courier to collect samples from our company; or send us the samples charge together with the courier cost by T/T.

2.How much the courier freight will be for the samples?

Courier freight depends on the quantity, weight and carton size and your area. you can use your courier company.

3.How can I get your Quotation Sheet?

Please send us your inquiry , drawings and your specifications by email or fax , we will offer you our price list, offer sheet and order information in one working day.

4.How to place an order?

Please send us your purchase order by email or fax. Or you can ask us to send you a Proforma Invoice for your order. We need to know the following information for your order:

* Shipping information - company name, street address, phone number, fax number, destination airport or sea port, transportation method (by courier, by air or by ocean container)

* Product information - model numbers, quantity, unit price and price term we reach to

* Delivery time required

* Payment terms

* Forwarder's contact details if necessary